Key Specifications / Features

Model No.: Hits: 14

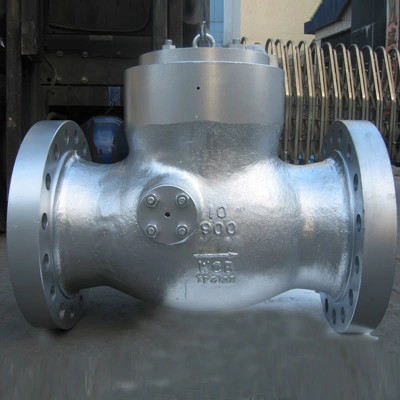

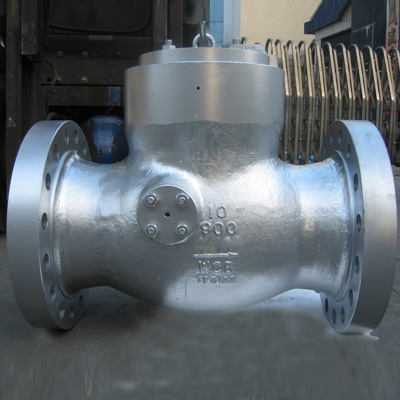

Pressure Seal Check Valve Provider: Pressure Seal Bonnet Check Valves, 1-1/2-24 Inch, Class 600-2500 LB, API 6D, ASME B16.34, RF, RTJ,NPT, BSPT,SW, BW, Grooved.

Request a quoteTags

Detail Information

Med Pressure Sealed Check Valves are intended for high pressure, high-temperature applications in all types of fluid except where severe coking is a factor. The design and material selections provide excellent service in steam-generation stations, industrial chemical plants and thermal power plants. Most Pressure Seal valves are offered in Cast Steel and Forged Steel body designs. These options make the Med Pressure Seal product line an excellent choice for users with various application requirements.

Med Pressure Sealed Check Valves provide the most efficient flow passage and sealing features possible, resulting in significant weight savings, easy installation and in-line maintenance. Featured with compact structure & Low emission service.

Design & Manufactured: API 6D, ASME B16.34, Equivalent.

P.T Ratings: ASME B16.34.

Face to Face dimensions: ASME B16.10.

Flanged Ends: ASME B16.5.

Butt-weld Ends: ASME B16.25.

Threaded Ends: ASME B1.20.1.

Socket-weld Ends: ASME B16.11.

Valves Marking: MSS SP-25.

Inspect & Tested: API 598.

Size Ranges: 1-1/2-24 Inch.

Pressure Ratings: Class 600-2500 LB, PN100-PN420.

Structures in Bolted or Pressure Sealed Union Cover.

Ends Connections in Flanged R.F or RTJ, Threaded NPT, BSPT, Welded S.W, B.W and Grooved.

Body Materials available in Cast Carbon Steel, Low Temp. Carbon Steel, Alloy Steel, Stainless Steel, Monel, Alu. Bronze, etc.

Trim Materials available in 13%Cr, ASTM A182 F11, ASTM A182 F22, SS 304, SS 304L, SS 316, SS 316L and other specials.

Optional H.F Overlayed.

Optional Bypass system & Counter-weight Assembly.