Key Specifications / Features

Model No.: Hits: 16

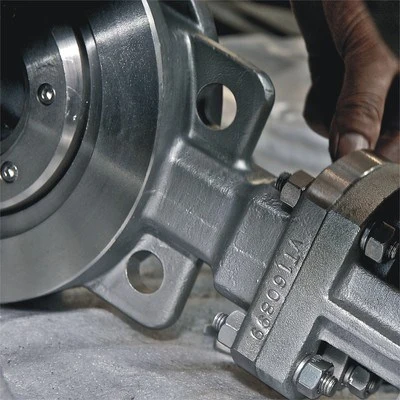

API 509 Eccentric Butterfly Valve Supplier: Wafer Eccentric Butterfly Valves, 2-48 Inch, Class 150-600 LB, Cast Carbon, Stainless, Alloy, Duplex steel.

Request a quoteTags

Detail Information

The Med Wafer Eccentric Butterfly Valves are designed and manufactured to API 509, with Eccentric structure, Center of the valve stem deviate from Disc Center to avoid the extrusion between disc and seat, then extend the service life of the valve.

Med Wafer Eccentric Butterfly Valve s are with main Features as below:

Lockable Lever.

Site maintenance.

Ease of automation.

Positive tight shut-off.

Optional top flanges to ISO 5211.

Qualified for both gaseous and liquid services.

Broad line of body and trim materials for a variety of medium services.

ISO 5752, BS 5155, API 609, MSS-SP-68, ASME B16.10, ASME B16.5, DIN 3202.

Materials: Cast Carbon Steel, Low Temp. Carbon Steel, Stainless Steel, Alloy Steel, duplex steel and etc.

Temperature: -20 ℃ - 150 ℃.

Pressure Ratings: ANSI Class 150-600 LB, PN10-PN100.

Size Ranges: 2-48 Inch, 50-1200mm (Larger sizes upon request).

Soft Seat: NBR, EPDM, VITON, PTFE.

Ends Connections: Wafer, Lugged, Double Flanged, Butt Weld or Grooved.

Actuations: Manual, Pneumatic, Electric, Hydraulic (Counterweight) & Electro-hydraulic.